DEEKON Textile, professional Functional Textile supplier for Tactical, Workwear and Outdoor industries.

Four (4) Key Points for Choosing the Best Military Combat Uniform Fabric

1- Adapt to Local Geographical Colors and Vegetation

2- Match Local Climate Conditions

1) the correct fabric composition

2) the correct yarn thickness

3) the correct density and way of weaving

3- Durability and Strength

1) Raw material selection (nylon, cotton, polyester, viscose, Nomex)

4- More Functions to Enhance Tactical Adaptability

1) Anti-infrared treatment

2) Mosquito Repellent Treatment

3) Antibacterial Treatment

4) Water and Oil Repellent Treatment

5) Moisture-Wicking Treatment

6) Stretchable fabric for great comfort

7) Anti-static

8) Fire-retardant

Military combat uniform fabric is a strategic material that directly ties to battlefield concealment, environmental adaptability, soldier safety, and long-term combat effectiveness. Unlike conventional clothing, military combat uniform fabric must withstand extreme wear, harsh climates, and complex tactical scenarios while balancing protection and comfort. This guide adheres to core tactical demands, elaborating on the key selection criteria from four critical dimensions to help you build a “functional tactical suit” tailored to actual missions.

Camouflage is the primary line of tactical concealment, and the selection of camouflage patterns and colors must be fully integrated with local geographical features and vegetation types to achieve the effect of “blending with the environment” and reduce the probability of detection by enemy naked eyes or optical equipment.

For jungle areas, prioritize camouflage patterns with green as the dominant tone, complemented by brown, black, and other auxiliary colors. The pattern should simulate the interlacing of leaves, branches, and grass with irregular edges to avoid obvious outlines—typical examples include the U.S. Army’s M81 Woodland camouflage and British DPM camouflage, designed for tropical and temperate jungles, ensuring effective integration with the jungle environment.

In rencent years, Multicam is of the most camouflage pattern designed for use in a wide range of environments and conditions which was developed and is produced by American company Crye Precision.[2] The pattern has found extensive adoption globally. Variants of it, some unlicensed, are in use with militaries worldwide, particularly with special forces/special operations forces units.

Climate conditions directly determine the comfort and adaptability of combat uniforms. The selection of fabric must be tailored to local temperature, humidity, with three core parameters—fabric composition, yarn thickness, and density—jointly determining the climate adaptability of the fabric.

1- Correct Fabric Composition

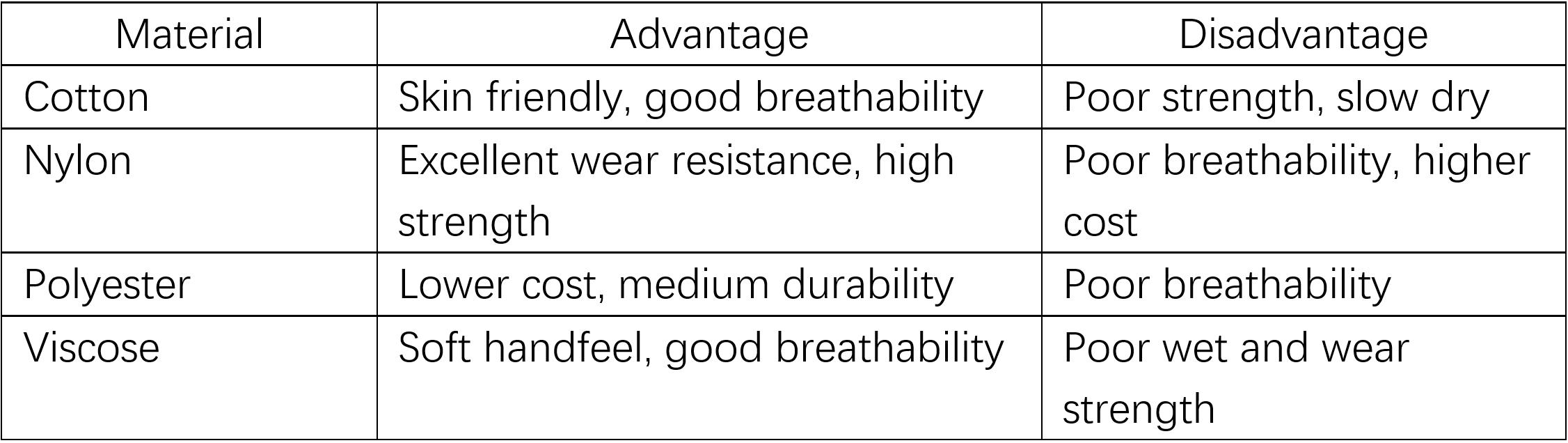

There are four main components for the military uniform fabric in current market, that are cotton, nylon, polyester, viscose. Each material has its own advantage and disadvantage. See table as below,

So, the cotton and viscose are with good hand feel, and good breathability, while the nylon and polyester are with good strength, and durability.

The most common composition on the market is 50% nylon and 50% cotton. This is the composition ratio used in many uniform fabrics of the US military because this fabric is suitable for most usage scenarios. The 50% nylon has very strong abrasion resistance, which ensures the durability of military uniforms, while the 50% cotton provides better comfort and breathability.

In high-temperature and high-humidity tropical areas, prioritize “breathability + quick-drying” by choosing blended fabrics with natural fibers as the main component and synthetic fibers as supplements. Like 65% cotton, 35% polyester, 80% cotton, 20% polyester, even we can make the fabric with 92% Long-staple cotton, 8% nylon to increase the comfort for the military uniforms.

2. Correct Yarn Thickness

Yarn thickness, expressed by “count”, directly affects fabric breathability and strength. Medium to high-count yarns (20-40 count) are preferred for combat uniforms. Thicker yarns (20-25 count) offer higher strength and wear resistance but lower breathability, suitable for high-wear scenarios like jungle combat. Thinner yarns (30-40 count) improve breathability but slightly reduce strength, ideal for tropical areas or low-intensity missions. The U.S. Army ACU combat uniform uses 32-count nylon-cotton blended yarn to balance tear strength and breathability.

3. Correct Density and Way of Weaving

Fabric density (warp×weft yarns per square inch) correlates with protection and breathability. For tropical areas, control density at 100×60 to ensure sufficient breathability; for cold or high-wear areas, increase density to 140×100 to enhance tear resistance and windproof performance. Test data shows that under the same yarn thickness and weave, 140×100 density fabric has 30% higher tear strength than 110×60, with a 20% reduction in air permeability.

Weave type determines fabric structure and performance: Plain weave is firm and wear-resistant but poorly breathable; twill weave (2/1 or 3/1) is soft, tear-resistant, and more breathable than plain weave, making it the most widely used for combat uniforms; Ripstop weave can be combined with density adjustment—reinforced yarns added at regular intervals prevent tearing from expanding without excessive sacrificing breathability. So, Twill ripstop weave is a good solution for increasing both breathability and tearing strength.

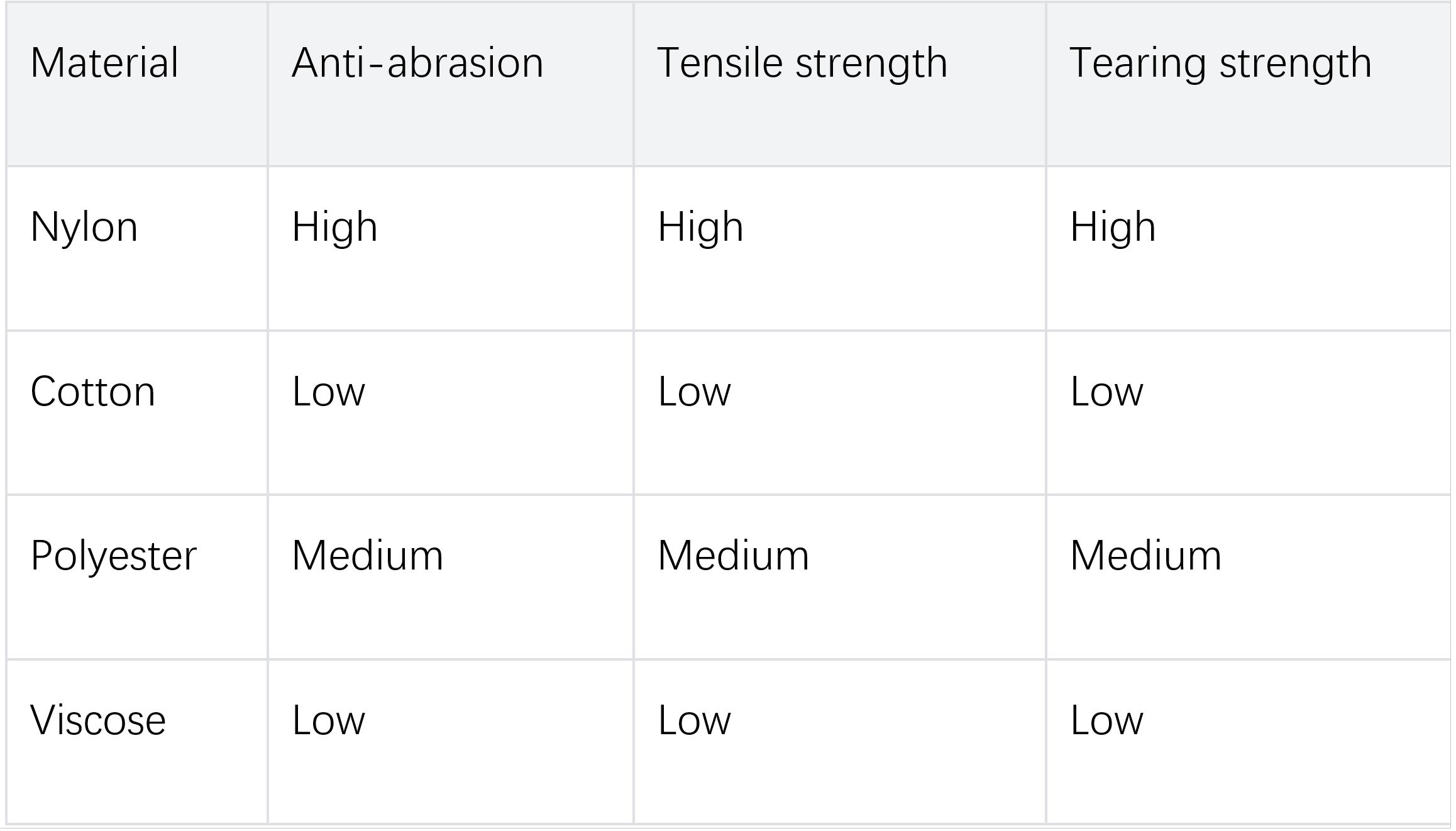

Battlefields are filled with harsh wear factors, including jungle thorns, gravel friction, equipment scratches, and frequent tactical movements. Durability and strength rely on rational raw material selection, with each material differing significantly in anti-abrasion, tensile strength, and tearing strength.

1. Raw Material Selection

Common materials for combat uniform fabrics include nylon, cotton, polyester, viscose. Their performance regarding abrasion resistance, tensile strength and tearing strength are summarized in the table below:

2. Advantages & Disadvantages of Each Material

• Nylon: Advantages include high strength (2.5 times that of cotton), excellent wear resistance (flat abrasion resistance ≥10,000 times, ASTM D4966), low water absorption (weight increase only 10% when wet), and fast drying. Disadvantages: Poor breathability, prone to stuffiness during long-term wear; melts and drips when burned (melting point ≈200℃), causing secondary burns. Rarely used alone, mostly as a blended component.

• Cotton: Advantages: Good breathability and moisture absorption (moisture regain 8%-10%), skin-friendly, no irritation, and no molten droplets when burned. Disadvantages: Low wear resistance (flat abrasion resistance 2,500-3,000 times), high water absorption (weight increase 80%-100% when wet), slow drying, poor wrinkle resistance, and shrinkage rate of 5%-8%.

• Polyester: Advantages: Medium durability, good wrinkle resistance, low shrinkage rate (≤2%), and strong UV resistance. Disadvantages: Poor moisture absorption (moisture regain 4%-5%), poor breathability, and slight irritation to the skin when soaked in sweat.

• Viscose: Advantages: Soft hand feel, good breathability and moisture absorption (similar to cotton), and natural luster. Disadvantages: Poor wet strength (strength decreases by 30%-50% when wet), poor wear resistance, and poor dimensional stability, prone to deformation.

The 50/50 nylon-cotton blend is the “golden ratio” for balancing durability and comfort, with flat abrasion resistance ≥200,000 cycles by ISO12947.2:2016, while the 65/ 35 poly-cotton is 50,000 cycles only. For high-demand scenarios, Nomex or aramid can be added to enhance strength and flame retardancy.

With the modernization of warfare, adding special functional treatments to combat uniform fabrics has become a key way to improve tactical advantages. The following eight functions can be selectively added based on mission scenarios:

1. Anti-infrared Treatment

Treat fabric with infrared shielding agents to reduce Infrared reflectivity of each color on the camouflage fabric to avoid detection by night vision binoculars at night. Deekon Functional Textiles with more than 10 years’ experience with anti-infrared fabrics.

2. Mosquito Repellent Treatment

In tropical and jungle regions, mosquitoes significantly reduce soldiers’ combat effectiveness. Therefore, we can add mosquito-repellent properties to military fabrics. Mosquito-repellent treated fabrics can form a long-lasting “mosquito-proof protective ring,” allowing soldiers to reduce external interference in mosquito-infested areas, maintain focused tactical awareness, and ensure sufficient physical reserves.

Antibacterial treatment is one of the core functional processes for military fabrics, its core function being to inhibit the growth of harmful microorganisms on the fabric in the harsh environment of the battlefield. When soldiers wear tactical uniforms during high-intensity combat, they sweat profusely. This sweat mixes with skin keratin, dirt and dust, leading to the growth of harmful microorganisms such as E. coli, Staphylococcus aureus, and Streptococcus in areas like the armpits, back, waistband, and ankles. The bio-antibacterial treatment agent used by Deekon Functional Textiles can inhibit more than 99% of these three types of bacteria and maintains a 75% antibacterial rate even after 150 washes.

4. Water and Oil Repellent Treatment

Deekon Functional Textiles’ oil- and water-repellent military fabrics achieve an oil-repellent rating of 5 and a water-repellent rating of 5.

Adopt hydrophilic-hydrophobic dual-structure finishing to quickly absorb sweat from the inner layer and transfer it to the outer layer for evaporation, keeping the skin dry. And performance remains stable after 50 washes—ideal for high-intensity missions.

6. Stretchable Fabric for Great Comfort

The requirements for combat clothing are becoming increasingly higher. Fabric elasticity is a crucial indicator. Since combat clothing doesn’t require elasticity in the warp direction, we only need to add elasticity in the weft direction. One method is to add approximately 3% spandex to the weft; the other method is to use Sorona elastic yarn as the weft yarn, which is more durable elasticity than spandex. We call it mechanical stretch fabric. Both methods can increase the elasticity in the weft direction.

7. Anti-static Treatment

Treat fabric with antistatic agents or blend conductive fibers to reduce static electricity accumulation, avoiding interference with electronic equipment and preventing static sparks from exposing positions in flammable environments.

8. Fire-Retardant Treatment

For high-risk scenarios (explosions, fires), flame-retardant combat uniforms are needed.

Nomex, flame-retardant viscose and Modacrylic are the three primary materials used for permanently flame-retardant military uniform fabrics. Nomex blends meet MIL-DTL-44436 (U.S. military).

In summary, selecting military combat uniform fabric requires a holistic approach to geographical adaptation, climate matching, durability, and functional enhancement. Each parameter and function must be tailored to mission scenarios to balance protection, adaptability, and comfort. As textile technology advances, more intelligent and versatile fabrics will continue to elevate the tactical performance of military combat uniforms. Deekon Functional Textiles specializes in the R&D and production of military, workwear and outdoor functional fabrics.

We sincerely invite you to get in touch with us for further cooperation and detailed information. Email:[email protected]

Layne | 01-26-2026 | Views 13 times

How to Choose the Best Military Combat Uniform Fabric? DEEKON Textile, professional Functional Textile supplier for Tactical, Workwear and Outdoor industries. Four (4) Key Points for Choosing the Best Military Combat Uniform Fabric 1- Adapt to Local Geographic...

Layne | 01-19-2026 | Views 84 times

Why Cordura Fabric Is the Top Choice for Tactical Bags? Tactical bag, as a core piece of equipment for military and police personnel on missions and outdoor enthusiasts exploring the wilderness, tactical bags must not only carry various supplies but also withstand w...

Layne | 09-03-2024 | Views 1,906 times

Sweatshirt Knit Fabric Series: Functions and Composition 1. Introduction to Sweatshirt Fabric Sweatshirt fabric is one of the most basic fabrics used in circular knitting. As the name suggests, it is used for making sweatshirts. In technical terms, it is know...

Layne | 09-02-2024 | Views 1,568 times

Are you looking for common swimwear fabrics? 1. Common Swimwear Fabrics In the blazing summer, it’s the season for swimwear to shine. So, what are the most commonly used fabrics for swimwear, and how should you select and care for them? 1.1 Lycra (DuPont L...

Layne | 09-01-2024 | Views 2,302 times

The Versatility of Polyester Stretch Fabric 1. Introduction Polyester stretch fabric is a standout in the textile industry, known for its flexibility, durability, and comfort. This fabric, made from a blend of polyester and elastane (or spandex), is widely us...

Layne | 08-31-2024 | Views 1,621 times

Nylon Stretch Fabric: The Perfect Blend of Strength and Flexibility 1. What is Nylon Stretch Fabric? Nylon stretch fabric is created by blending nylon fibers with elastane or spandex. Nylon itself is a synthetic fiber known for its toughness, resistance to we...

Contact us now for a free consult!