Tactical bag, as a core piece of equipment for military and police personnel on missions and outdoor enthusiasts exploring the wilderness, tactical bags must not only carry various supplies but also withstand wear and tear from complex environments. The performance of their fabric directly determines the reliability and service life of the equipment. Among numerous fabrics, Cordura has become the benchmark fabric in the global tactical bag industry, thanks to its core advantages of ultra-high wear resistance, tear resistance, and lightweight properties. From professional military-standard backpacks to high-end outdoor tactical bags, Cordura fabric is ubiquitous. This article will take you deep into the adaptation logic between Cordura fabric and tactical bags, confirm its advantages through data and cases, interpret the strict standards of the U.S. military for Cordura materials, and introduce reliable supply partners for high-quality Cordura fabric.

1. Introduction: Core Performance Requirements of Tactical Bags and the Industry Status of Cordura Fabric

2. Basic Understanding of Cordura Fabric: Origin, Core Characteristics, and Adaptation Logic with Tactical Bags

3. Data + Cases: Core Advantages of Cordura Fabric for Tactical Bags

4. Detailed Explanation of U.S. Military Standards: Specific Requirements for Cordura Materials Used in Tactical Bags

5. Deekon Functional Textile — A Professional Manufacturer and Supplier of Cordura Fabric

Cordura originally developed by DuPont and now owned by INVISTA, Cordura fabric was born out of the demand for “high-strength, lightweight” fibers. Initially, the nylon 66 fiber was developed to replace cotton thread in tires. With its excellent performance, it was gradually applied in the military industry and became one of the core fabrics for military equipment. Today, Cordura has become synonymous with high-performance wear-resistant fabrics. Its core material is high-strength nylon 66 yarn, with common specifications including 330D, 500D, 750D, 1000D, etc. It can be processed through various weaving methods such as plain weave and Oxford weave, and matched with post-finishing processes such as PU coating and waterproof lamination to accurately meet the usage scenario requirements of different tactical bags.

From the perspective of the usage needs of tactical bags, they must simultaneously meet the four core demands of “wear resistance and durability, lightweight, stable load-bearing, and environmental adaptability”. The characteristics of “lightweight, strong, tough, and stable” of Cordura fabric perfectly match these demands. Whether it is scratches from branches in the jungle, friction from rocks in mountainous areas, or wind and rain erosion outdoors, Cordura fabric can provide comprehensive performance support for tactical bags, which is the core reason why it has become the preferred fabric for tactical bags.

1. Ultra-High Wear Resistance: Core Guarantee for Extending the Service Life of Tactical Backpacks

Tactical bags often face continuous friction during use, and wear resistance is a core assessment index. Authoritative data shows that at the same weight, the durability of Cordura fabric is twice that of standard nylon fabric, three(3) times that of polyester fabric, and even ten(10) times that of cotton canvas.

Case Confirmation: There are many top Tactical Brands used Cordura for their Tactical Bags, Arc Teryx LEAF, Mystery Ranch, 5.11 Tactical, Helikon-Tex, CamelBak, Blackhawk, Condor Outdoor, Tasmanian Tiger, etc

In the actual test by outdoor adventure enthusiasts, after 6 months of high-intensity use such as jungle trekking and rock climbing, the contact surface of the backpack only showed slight wear, no pilling or holes, and its service life is more than three times that of ordinary nylon backpacks.

2. Excellent Tear Resistance and High Strength: Bottom Line for Load-Bearing Safety

Tactical bags need to carry various equipment and often face external tearing and heavy object compression, so tear resistance and tensile strength are crucial. Tested according to the ASTM D2261 standard, the tear strength of Cordura fabric can reach more than 200N, far exceeding the 80-120N of ordinary nylon fabric; taking 1000D military-standard Cordura fabric as an example, its warp tensile strength can reach at least 500 pounds, and the weft tensile strength can reach at least 300 pounds, which can easily carry heavy objects without deformation.

3. Strong Environmental Adaptability: Balancing Waterproof, Quick-Drying, and Concealment

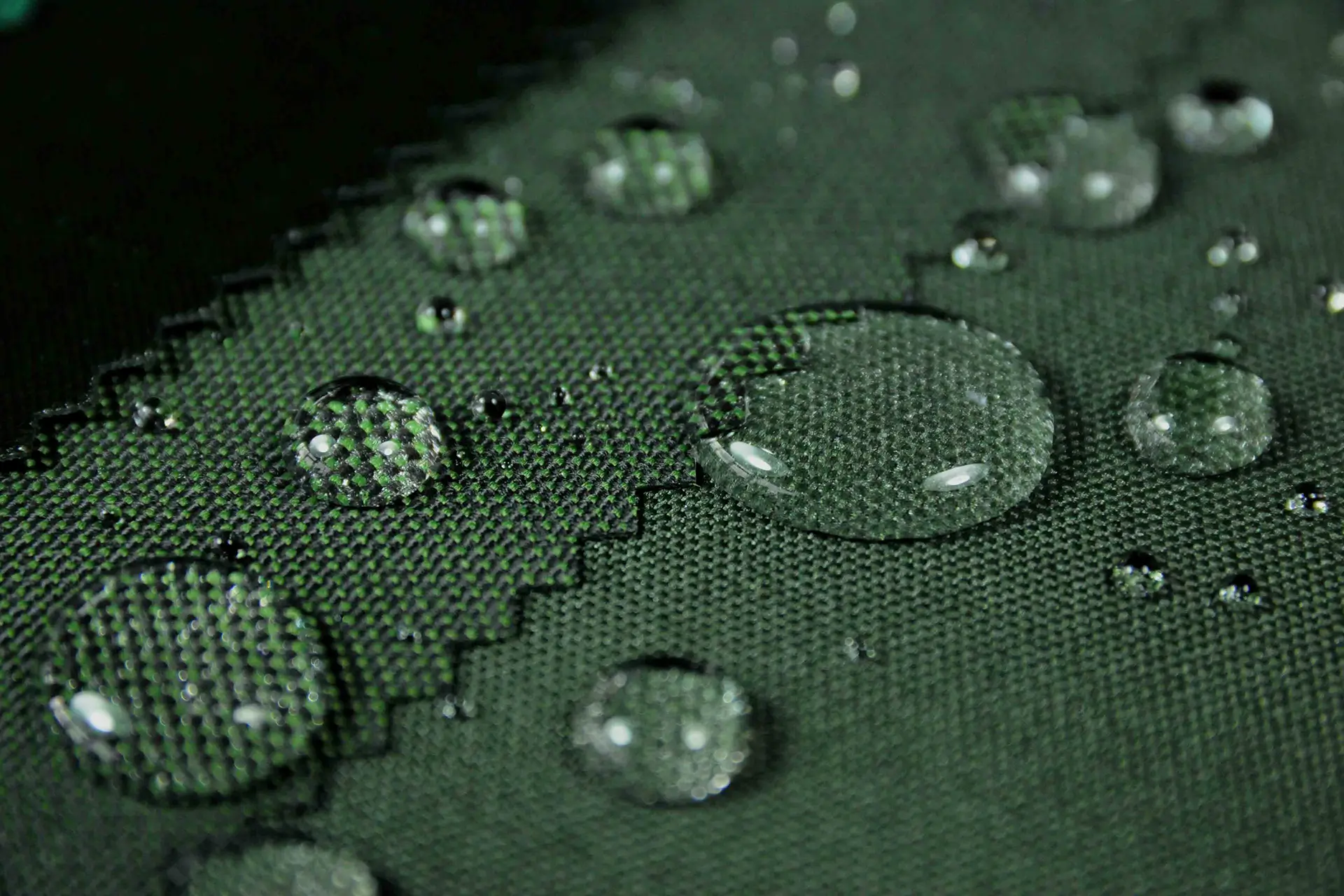

Tactical bags need to adapt to a variety of complex environments, and Cordura fabric can achieve multiple environmental adaptability through post-finishing processes. Cordura fabric treated with PU coating has a waterproof rating of 3000mm-20000mm, which can effectively resist moderate to heavy rain; it has excellent quick-drying performance, and the water evaporation rate is more than twice that of cotton fabric. Even if wetted by rain, it can dry quickly to avoid moisture damage to the equipment inside the backpack. At the same time, military-standard Cordura fabric adopts a matte finish, which can reduce light reflectivity. Combined with an anti-infrared (IR) coating, it can reduce the infrared transmittance, improving concealment in tactical scenarios and meeting the concealment needs of military operations.

4. Stable Color and Easy Care: Maintaining Stable Performance After Long-Term Use

Cordura fabric adopts solution dyeing technology, with excellent color fastness. The wash fastness can reach grade 4 or above, and the rub fastness can reach grade 4-5. Even after 50 industrial washes, it can still maintain uniform color without obvious fading. At the same time, it has mildew resistance and corrosion resistance. After being used in a humid and hot jungle environment, it does not require complex care and can be kept clean with simple wiping, reducing the maintenance cost of tactical equipment.

As a benchmark user of tactical equipment, the U.S. military has formulated strict standards for the use of Cordura materials to ensure that they can meet the needs of extreme battlefield environments. The core standard is MIL-DTL-32439 (Military Detail Specification: Nylon Fabrics), and the specific requirements cover the following core dimensions:

1. Material and Specification Requirements

The U.S. military stipulates that Cordura fabric used in tactical bags must be woven with high-toughness nylon 66 yarn authorized by INVISTA. Common specifications need to match the four grades of Type I (1000D), Type II (750D), Type III (500D), and Type IV (330D) in the MIL-DTL-32439 standard. Different specifications correspond to different tactical scenarios — 1000D is used for heavy tactical backpacks (such as load-carrying equipment), 500D for medium tactical backpacks, and 330D for lightweight assault backpacks.

2. Core Performance Index Requirements

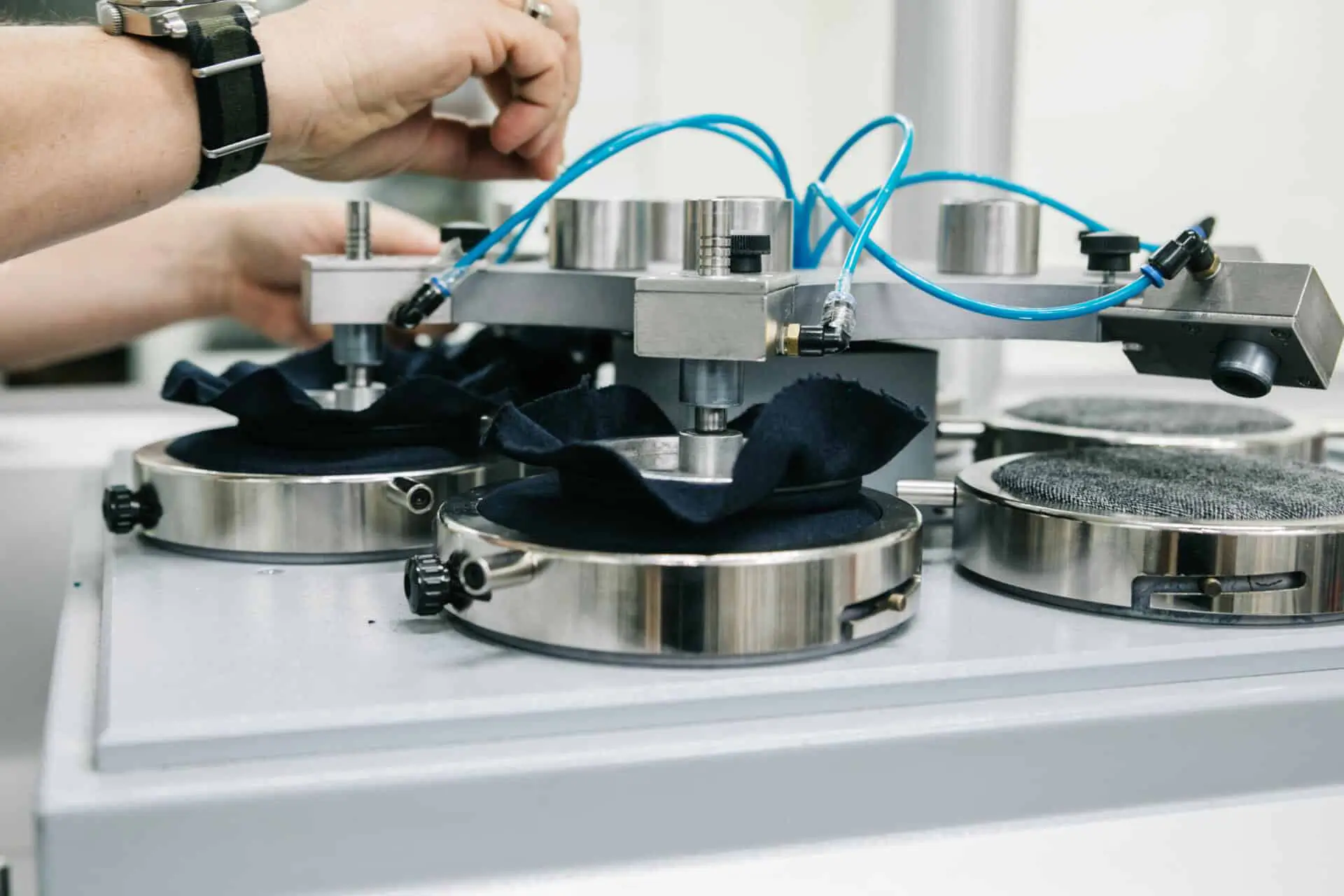

• Wear Resistance: According to the Taber Abrasion Test (ASTM D3384), the wear resistance cycle count of 1000D Cordura fabric shall not be less than 700 times; after 5 industrial washes (AATCC 135 standard), the wear resistance attenuation shall not exceed 20%.

• Tensile and Tear Strength: The warp tensile strength of 1000D Cordura fabric shall be at least 500 pounds, and the weft tensile strength shall be at least 300 pounds (ASTM D5034 standard); the tear strength shall not be less than 200N (ASTM D2261 standard) to ensure no damage under heavy load and external tearing.

• Waterproof Performance: Cordura fabric treated with PU coating shall have a hydrostatic waterproof rating of not less than 3000mm, which can resist moderate to heavy rain; the surface shall have a durable water repellent (DWR) function, so that water droplets can roll off quickly when contacting the fabric without penetration.

• Concealment and Color Fastness: The fabric shall have a mat texture with a light reflectivity of less than 15% to avoid exposure to targets due to reflection on the battlefield; the infrared reflectivity shall comply with the U.S. military NIR standard, which can reduce the probability of infrared detection without additional treatment; in terms of color fastness, the wash fastness and rub fastness shall be at least grade 4, and the color uniformity deviation of fabrics from different batches shall not exceed 5%.

• Safety Performance: In the vertical burning test (ASTM 6413-99 standard), it shall reach the “no melting and no dripping” level to avoid melting and burning the user in high-temperature environments; it shall have mildew resistance and corrosion resistance, and no mildew shall occur when placed in a high-temperature and high-humidity environment for 72 hours.

High-quality tactical bags are inseparable from the quality control of the source fabric. For tactical equipment brands and outdoor product manufacturers, choosing a Cordura fabric supplier with professional R&D and production capabilities is the core prerequisite for ensuring product quality. As a Functional Textiles Supplier for Tactical, Workwear and Outdoor Industries, Deekon Textile has become a reliable supplier of Cordura fabric by complete production system, strict quality control, and rich customization experience, providing high-quality fabric solutions for the tactical gears industry.

Deekon Textile focuses on the design, R&D, production, and sales of high-quality functional fabrics. It has a full-process vertically integrated production capacity from raw material procurement, weaving, dyeing and finishing to post-finishing, which can efficiently meet the needs of large-volume orders. The company has a deep grasp of the core production technology of Cordura fabric and can accurately produce full-specification Cordura fabrics such as, 500D, and 1000D, which are compatible with the U.S. military MIL-DTL-32439 standard and internationally accepted test standards such as ASTM, AATCC and ISO. Key performance indicators such as wear resistance cycle count, tensile strength, and color fastness have reached the top level in the industry.

In response to the personalized needs of tactical bags, Deekon Textile can provide customized services: supporting various post-finishing processes such as PU/TPU coating, waterproof lamination, fire-retardant treatment, matte finish, and anti-infrared treatment to achieve multiple functions such as waterproof, concealment, and quick-drying;

Over the years, Deekon Textile has always adhered to the concept of “quality first, integrity-based operation” and built a complete quality control system. Each batch of Cordura fabric must undergo more than 20 tests such as wear resistance, tensile strength, and color fastness to ensure stable and reliable product quality. At present, the company has successfully served many mainstream tactical equipment brands and outdoor product retailers around the world, with products covering tactical backpacks, combat uniforms, outdoor equipment and other fields, winning wide recognition in the market. If you have production needs for Cordura fabric, whether it is bulk procurement, customized R&D or ODM cooperation, you can directly contact Deekon Textile to obtain one-stop professional solutions.

Layne | 01-26-2026 | Views 12 times

How to Choose the Best Military Combat Uniform Fabric? DEEKON Textile, professional Functional Textile supplier for Tactical, Workwear and Outdoor industries. Four (4) Key Points for Choosing the Best Military Combat Uniform Fabric 1- Adapt to Local Geographic...

Layne | 01-19-2026 | Views 84 times

Why Cordura Fabric Is the Top Choice for Tactical Bags? Tactical bag, as a core piece of equipment for military and police personnel on missions and outdoor enthusiasts exploring the wilderness, tactical bags must not only carry various supplies but also withstand w...

Layne | 09-03-2024 | Views 1,906 times

Sweatshirt Knit Fabric Series: Functions and Composition 1. Introduction to Sweatshirt Fabric Sweatshirt fabric is one of the most basic fabrics used in circular knitting. As the name suggests, it is used for making sweatshirts. In technical terms, it is know...

Layne | 09-02-2024 | Views 1,568 times

Are you looking for common swimwear fabrics? 1. Common Swimwear Fabrics In the blazing summer, it’s the season for swimwear to shine. So, what are the most commonly used fabrics for swimwear, and how should you select and care for them? 1.1 Lycra (DuPont L...

Layne | 09-01-2024 | Views 2,302 times

The Versatility of Polyester Stretch Fabric 1. Introduction Polyester stretch fabric is a standout in the textile industry, known for its flexibility, durability, and comfort. This fabric, made from a blend of polyester and elastane (or spandex), is widely us...

Layne | 08-31-2024 | Views 1,621 times

Nylon Stretch Fabric: The Perfect Blend of Strength and Flexibility 1. What is Nylon Stretch Fabric? Nylon stretch fabric is created by blending nylon fibers with elastane or spandex. Nylon itself is a synthetic fiber known for its toughness, resistance to we...

Contact us now for a free consult!